General properties allegheny ludlum s al 17 4 precipitation hardening alloy s17400 type 630 is a chromium nickel copper precipitation hardening stainless steel used for applica tions requiring high strength and a moderate level of corrosion resistance.

17 4 ph stainless steel magnetic properties.

Air melted armco 17 4 ph stainless steel will meet the magnetic particle inspection requirements of aerospace materials specification ams 2303.

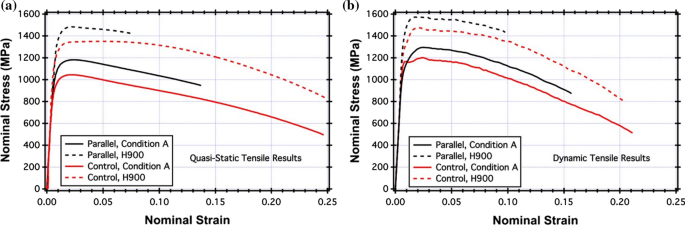

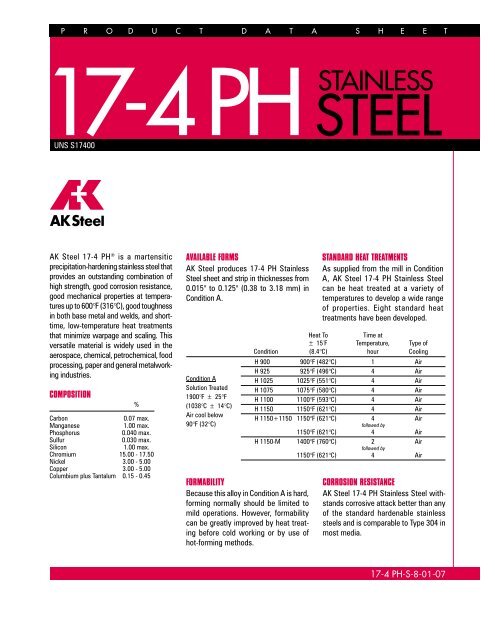

Very high yield strength up to 1100 1300 mpa 160 190 ksi can be achieved.

17 4 ph stainless strip is the most widely used of all precipitation hardening stainless steels.

High strength is maintained to ap proximately 600 f 316 c.

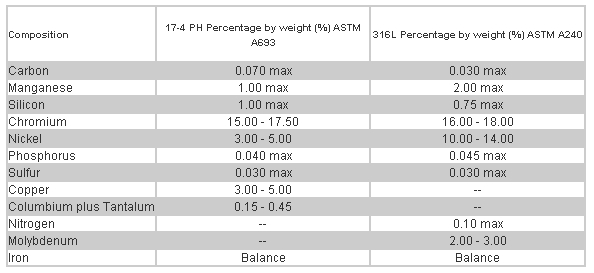

Alloy 17 4ph is a precipitation hardening martensitic stainless steel with cu and nb cb additions.

60 000 q a topics education aloha fun topic 33939 is type 17 4ph stainless steel magnetic.

Consumable electrode vacuum arc remelted armco 17 4 ph vac ce meet the magnetic particle inspection requirements of aerospace materials specification ams 2300.

In addition it is more cost effective than many high nickel non ferrous alloys.

17 4 stainless steel is an age hardening martensitic alloy combining high strength with the corrosion resistance of stainless steel.

Also known as uns 17400 is a grade of martensitic precipitation hardened stainless steel.

For applications requiring high strength and hardness plus corrosion resistance this alloy is an outstanding choice.

17 4 ph is a martensitic chromium nickel copper precipitation hardening stainless steel that provides an outstanding combination of high strength good corrosion resistance good mechanical properties at temperatures up to 600ºf 316ºc.

A detailed set of properties chemical composition range and applications are provided.

17 4 ph stainless steel mechanical properties ak steel 17 4 ph stainless steel provides excellent mechanical properties.

It contains approximately 15 17 5 chromium and 3 5 nickel as well as 3 5 copper.

Alloy 17 4ph can be easily welded and processed by standard shop fabrication practices.

The name comes from the chemical makeup which is approximately 17 chromium and 4 nickel.

It is used in applications where the combination of moderate corrosion resistance and unusually high strength are required.

Ce stainless steel should be considered.

It s a martensitic steel that combines high strength corrosion resistance impecable mechanical properties up to 600 f and good toughness.

Sae type 630 stainless steel more commonly known as 17 4 ph or simply 17 4.

Mechanical properties can be optimized with heat treatment.

Stainless steel in most environments and is generally superior to the 400 series stainless steels.

This alloy is typically furnished in condition a annealed but can be cold rolled to various temper.

In relation to iron.

.jpg)