17 4 ph steel contains 4 copper and may be hardened by a single low temperature precipitation hardening heat treatment producing excellent mechanical properties at a high strength level.

17 4 ph stainless steel density.

17 4 ph is a martensitic precipitation hardening age hardening stainless steel that can provide both high strength and excellent corrosion resistance.

H 1150 density is 0 284.

Table 2 typical mechanical properties property.

17 4 ph stainless steel 3 17 4 ph stainless steel provides excellent mechanical properties.

Grade 17 4 stainless steel is annealed at 1038 c 1900 f for 0 5 h followed by cooling rapidly.

In addition it is more cost effective than many high nickel non ferrous alloys.

17 4 stainless steel is capable of attaining a wide range of strength and toughness properties depending on the precipitation or aging temperature used in hardening.

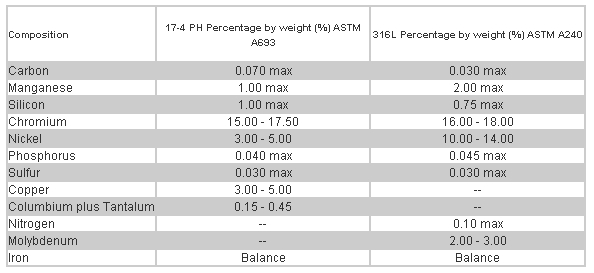

General properties allegheny ludlum s al 17 4 precipitation hardening alloy s17400 type 630 is a chromium nickel copper precipitation hardening stainless steel used for applica tions requiring high strength and a moderate level of corrosion resistance.

17 4 stainless steel 17 4 uns s17400.

17 4 ph provides this high strength in combination with good mechanical properties at temperatures of up to 600 f 316 c.

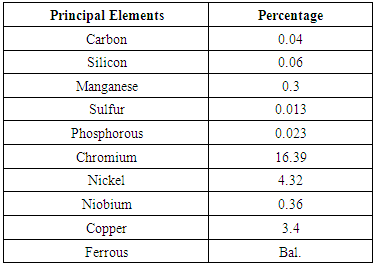

The name comes from the chemical makeup which is approximately 17 chromium and 4 nickel.

H 1075 density is 0 283 lb in 3.

Stainless 17 4 ph 1 888 282 3292 upmet com type 17 4 ph stainless steel is the most widely used of all of the precipitation hardening stainless steels.

High strength is maintained to ap proximately 600 f 316 c.

For applications requiring high strength and hardness plus corrosion resistance this alloy is an outstanding choice.

17 4 ph stainless steel mechanical properties ak steel 17 4 ph stainless steel provides excellent mechanical properties.

Type 17 4 is the most common grade of martensitic precipitation hardenable ph alloys.

In the annealed solution treated condition condition a the density of this material is 0 280 lb in 3.

For applications requiring high strength and hardness plus corrosion resistance this alloy is an outstanding choice.

H 900 density is 0 282 lb in 3.

It contains approximately 15 17 5 chromium and 3 5 nickel as well as 3 5 copper.

Sae type 630 stainless steel more commonly known as 17 4 ph or simply 17 4.

Powerful equipments are required for forming this alloy because it is stronger than the regular steel.

In addition it is more cost effective than many high nickel non ferrous alloys.

Its valuable combination of properties gives designers opportunities to add reliability to their products while simplifying fabrication and often reducing costs.

Also known as uns 17400 is a grade of martensitic precipitation hardened stainless steel.